By IndraStra Global Engineering Team

|

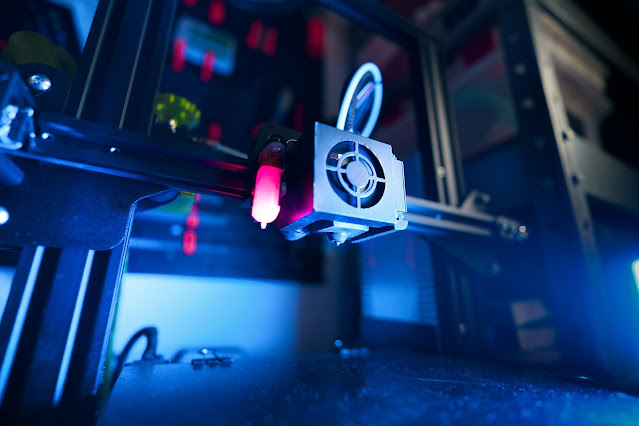

| Cover Image Attribute: 3D Printer in Close Up / Source: Jakub Zerdzicki, Pexels |

With the pace of warfare quickening and new threats emerging without warning, the ability to rapidly design, test, and deploy operational solutions has evolved from a strategic advantage into a necessity for survival on the modern battlefield. One capability that illustrates this shift is rapid prototyping. Encompassing techniques such as additive manufacturing, CNC machining, and modular system integration, rapid prototyping empowers defense establishments to sidestep the traditionally sluggish, bureaucratic procurement cycles that have long hampered military innovation. This capability is not merely a technological luxury but a strategic necessity, enabling armed forces to respond to emerging threats with agility and precision. From the high-altitude plateaus of the Himalayas to the contested waters of the Pacific, rapid prototyping is reshaping how militaries innovate, adapt, and maintain operational superiority in dynamic combat environments.

The essence of rapid prototyping lies in its ability to compress the timeline from concept to operational deployment. Traditional military procurement, often spanning years or even decades, is ill-suited to the demands of modern warfare, where adversaries exploit asymmetric tactics and emerging technologies like hypersonic missiles or swarming drones. Rapid prototyping leverages a suite of advanced manufacturing techniques to produce functional prototypes or end-use parts in days or weeks. Additive manufacturing, or 3D printing, is a linchpin of this approach. Technologies like Fused Deposition Modeling (FDM) enable field repairs and the construction of lightweight UAV airframes, prized for their low cost and portability. Stereolithography (SLA) delivers high-precision components like cockpit switches or optical housings, critical for sensitive aerospace applications. Selective Laser Sintering (SLS) produces durable tactical equipment and medical prosthetics, while Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) craft complex, high-strength metal parts for aircraft engines and missile components. Beyond additive manufacturing, CNC machining provides operational-grade prototypes for weapon systems and aircraft landing gear, while hybrid approaches combining additive and CNC finishing create lightweight yet precise components like UAV wing spars. These technologies, alongside others like vacuum casting, binder jetting, and wire arc additive manufacturing (WAAM), form a versatile toolkit that enables militaries to iterate designs rapidly and deploy solutions tailored to specific operational needs.

A compelling example of this paradigm is Anduril’s Arsenal Platform in the United States. Designed to produce autonomous weapons at scale, Arsenal integrates artificial intelligence with advanced manufacturing to streamline the development of next-generation defense systems. By leveraging modular system integration and additive manufacturing, Anduril can rapidly prototype and deploy autonomous drones, sensors, and other systems, reducing the time from design to battlefield deployment. This approach allows for continuous iteration based on real-world feedback, ensuring that systems remain relevant against evolving threats. The platform’s ability to produce complex, AI-driven systems at scale reflects the power of combining rapid prototyping with advanced software, delivering a level of adaptability that traditional procurement struggles to match. However, Arsenal’s reliance on proprietary technologies and AI raises questions about scalability across diverse military contexts and the potential risks of over-dependence on automated systems in chaotic combat environments.

In contrast, India’s Zorawar Light Tank illustrates rapid prototyping in a more traditional defense development framework. Developed by the Defence Research and Development Organisation (DRDO) and Larsen & Toubro (L&T), the Zorawar was designed to meet the Indian Army’s need for a lightweight, agile tank capable of operating in the high-altitude terrain of Ladakh, where conventional heavy armor struggles. Unlike additive manufacturing-driven projects, the Zorawar’s rapid prototyping focused on a compressed concept-to-prototype cycle for a complex system. By integrating modular design principles and leveraging existing technologies, DRDO and L&T produced a functional prototype in a fraction of the time required for traditional tank development. The Zorawar’s 25-ton design, equipped with advanced fire control systems and missile capabilities, was tailored to counter threats in mountainous regions while maintaining deployability via air transport. This example highlights the flexibility of rapid prototyping beyond 3D printing, demonstrating how modular integration and iterative testing can accelerate the development of large-scale systems. Yet, the Zorawar project encountered challenges, particularly in balancing speed with rigorous testing to guarantee reliability in extreme conditions — exposing the trade-offs embedded in rapid development cycles.

The battlefield in Ukraine offers a starkly different perspective, where rapid prototyping has fueled asymmetric innovation in the face of existential threats. Operation Spider's Web, a Ukrainian initiative to deploy low-cost drones against Russian airbases, exemplifies how rapid prototyping can enable unconventional warfare. By using FDM and PolyJet printing to produce lightweight drone airframes and communication device housings, Ukrainian forces created a fleet of affordable, expendable UAVs capable of long-range strikes. These drones, often assembled in makeshift workshops, were enhanced by the integration of ArduPilot, an open-source autopilot software widely used for UAV control. ArduPilot’s flexible architecture allowed Ukrainian engineers to rapidly customize flight control systems, enabling drones to navigate complex environments and execute precise missions. This open-source platform, combined with additive manufacturing, facilitated quick iterations based on battlefield feedback, ensuring that drones could be adapted to evade Russian countermeasures like electronic jamming. However, the reliance on low-cost materials and simplified designs raises concerns about durability and scalability, as well as the ethical implications of deploying rapidly prototyped weapons in high-stakes conflicts. Operation Spiderweb illustrates both the democratizing potential of rapid prototyping and the risks of prioritizing speed over robustness.

Australia’s SPEE3D metal 3D printers further highlight the practical applications of rapid prototyping in field conditions. Using cold spray technology, SPEE3D enables the rapid production of metal parts, such as tank tracks or helicopter rotor components, without the heat distortion associated with traditional metal additive manufacturing. Deployed by Australian forces and shared with allies, SPEE3D printers have been used to repair critical equipment in austere environments, enhancing operational readiness. The technology’s ability to produce functional parts in hours rather than weeks addresses the logistical challenges of maintaining equipment in remote or contested areas. For instance, cold spray printing can restore a damaged tank track in the field, reducing downtime and the need for complex supply chains. Yet, the technology is limited to specific materials and applications, and its high initial cost may constrain widespread adoption, particularly for smaller militaries or those with limited budgets.

The U.S. Navy’s integration of 3D printers aboard the USS Essex (LHD-2) and USS Bataan (LHD-5) exemplifies how rapid prototyping enhances operational resilience at sea. By installing additive manufacturing systems on these amphibious assault ships, the Navy can produce replacement parts on-demand, from structural brackets to medical prosthetics. This capability reduces reliance on shore-based supply chains, a critical advantage in prolonged deployments or contested maritime environments. For example, SLS and DMLS printers aboard these ships can fabricate durable components for aircraft or weapon systems, while binder jetting supports the production of non-critical parts like sand molds for casting. The Navy’s experience demonstrates the logistical benefits of in-situ manufacturing, but it also highlights challenges, such as the need for trained personnel to operate complex systems and the limitations of onboard material inventories. Scaling this capability across a fleet requires significant investment in training and infrastructure, raising questions about cost-effectiveness versus traditional logistics.

The strategic advantages of rapid prototyping are undeniable. By enabling militaries to bypass lengthy procurement cycles, these technologies ensure that solutions can be fielded before threats evolve. Additive manufacturing techniques like Continuous Liquid Interface Production (CLIP) and WAAM allow for ultra-fast production of complex parts, while CNC machining and hybrid approaches deliver precision for operational-grade components. Modular system integration, as seen in the Zorawar and Arsenal Platform, facilitates rapid iteration and scalability. In dynamic combat environments, where adversaries deploy novel tactics or technologies, this agility can mean the difference between mission success and failure. For instance, the ability to rapidly prototype UAV fairings using vacuum casting or sensor casings via CLIP allows forces to adapt to electronic warfare advancements in real time. Similarly, 3D-printed tooling and jigs streamline assembly lines for aircraft and missile systems, reducing production bottlenecks.

Yet, rapid prototyping is not without its challenges. The emphasis on speed can compromise quality, as seen in Operation Spiderweb’s reliance on low-cost, potentially less durable drones. Material limitations in additive manufacturing, particularly for high-stress applications like aircraft engine parts, require careful consideration of trade-offs between speed and performance. Technologies like DMLS and SLM, while capable of producing complex metal geometries, are expensive and energy-intensive, limiting their accessibility. Moreover, the decentralized nature of rapid prototyping, while empowering, introduces risks of inconsistency and lack of standardization, particularly in multinational operations. Cybersecurity is another concern, as digital designs transmitted to field printers could be vulnerable to interception or tampering. Finally, the reliance on advanced manufacturing requires skilled operators and robust supply chains for raw materials, which may be difficult to maintain in austere environments.

Ultimately, the convergence of these technologies and their applications enables armed forces to respond to evolving threats with unprecedented speed — from designing light tanks for high-altitude warfare to repairing naval components at sea. Yet, their success hinges on carefully balancing speed with reliability, cost with capability, and innovation with standardization. As militaries continue integrating these tools into their arsenals, they must confront the logistical, ethical, and operational challenges that accompany such rapid advances. Rapid prototyping is no panacea; it is a powerful enabler — one that demands strategic foresight and technical discipline to ensure the solutions it delivers are not only expedient but enduring.

Apple News, Google News, Feedly, Flipboard, and WhatsApp Channel

COMMENTS